Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

500 tph Stone crusher plant introduction:

Stone crushing plant is primarily involved in the manufacture of aggregates (coarse aggregates, crusher run, rock sand, fine aggregates) from limestone, granite, andesite, etc. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering.

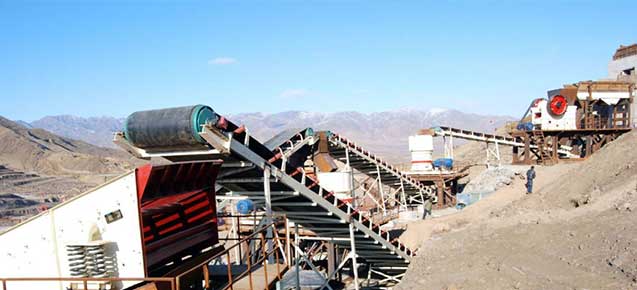

The stone crusher plant is generally composed of vibrating feeder, crushing machines, vibrating screen, belt conveyor and other equipment. The crushed stone production line is generally divided into coarse (primary), secondary and fine crushing according to its output fineness. The final size is 0-6mm(0-1/4’’), 6-12mm(1/4’’-1/2’’), 12-25mm( 1/2’’-1’’)(or other sizes according to your need) as aggregate for construction. It is suitable for application in hydropower, highway and urban construction, etc.

MGM machinery has 20+ years of experience in the stone crushing production line. We are skilled in the production plant design and has a high-cost performance. MGM stone crusher plant and stone crushing equipment have been sold to hundreds of countries, such as Indonesia, Philippines, Vietnam, Malaysia, India, Pakistan, Kenya, the USA, Ghana, Zimbabwe, America, Australia Canada, Peru, Columbia, Guatemala, Uzbekistan, Russia etc.

| Equipment configuration | Hopper (made on site), vibrating feeder ZSW1100x4900, jaw crusher PE900x1200, cone crusher HPC400/CS220 or impact crusher PF132, Vibrating screen, Belt conveyor. |

| Raw materials | Limestone, Granite, Basalt, Quartz, River stone etc. |

| Feed Size | less than 750mm |

| Capacity | 250-500t/h |

| Finished product | 0-6mm, 6-12mm, 12-25mm, 25-40mm |

| Application | The stone crushing equipment are used to produce aggregate of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

| Features | 1. Low operating cost and high crushing rate;2. Energy saving, large output and simple maintenance, in line with the national building sand standards;3. Uniform particle size of finished products, reasonable configuration. |

1.Raw material dump into the hopper by loader forklift, then hard rocks are fed into jaw crusher evenly and continuously by vibrating feeder for primary crushing.

2.Then the coarsely crushed materials are conveyed to secondary crusher (according to material hardness and output sizes request),secondary stone crusheing equipment can choose impact crusher, CS cone crusher, HP multi cylinders cone crusher and DG single cylinder cone crusher.

3.The final crushed material goes to vibrating screen to classify final qualified products according to different size ranges as stock pile for sale, or for road builidng use. Unqualified materials will be carried back to the stone crushing equipment for recrushing. This is closed circuit crushing process. The full set stone crushing plant will be more efficiency.

4.Customer can classify final products according to different size ranges. All the final products are up to the related standards within and beyond China. Dust is generated during the working process while the dust control units( such as pulse dust collector)are needed for environmental protection.