Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

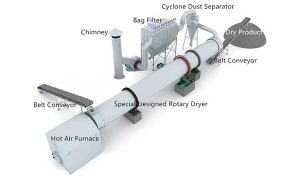

Rotary dryer is a kind of continuous rotating drum drying equipment with direct heating source. It is used to dry limestone, sand, coal, slag, clay, wood chips,sawdust, mining powder etc.

Rotary dryer is a kind of continuous rotating drum drying equipment with direct heating source. It is used to dry limestone, sand, coal, slag, clay, wood chips,sawdust, mining powder etc.

Rotary dryers are useful in a variety of industrial applications and choosing the right dryer can enhance the efficiency of your entire materials processing system.The following are the general principles for the selection of drying equipment:

Material properties. Different material characteristics will affect drying efficiency. To ensure that thermal processing meets production targets. When selecting a rotary dryer, consider key material characteristics such as: Water content of raw material, the water content of the air outlet meets the standard, the specific heat of the material being processed, heat transfer characteristics of the material being processed, material granule size, material surface quality (abrasive, corrosive, etc.).

Direct or Indirect Heat application. Direct heat rotary dryers pass a stream of drying air through the drum. The drying air is directed in either a co-current flow (flowing the same direction as the material), or counter-current flow (moving in the opposite direction of the material). Direct dryers are the most common choice for drying bulk solids. If material to be dried cannot come into contact with oxygen, or needs a completely inert environment, an indirectly heated rotary dryer is a choice.

Rotary dryer plant surroundings. Things such as the surrounding atmosphere, air temperature, humidity, and elevation, will affect the dryer’s performance. For example, an increase in elevation means a decrease in the amount of oxygen in the atmosphere, making the air less dense and less combustible. Therefore, the dryer’s fan size may need to be increased to compensate at higher elevations.

A large number of components can be customized to meet most processing requirements. Additional customizations such as percussion systems, sealing options and structural materials can be combined to create an efficient drying solution that suits your unique processing requirements.

Drying factors can be adjusted, such as concentration of feeding liquid/thickness of material film, temperature of heating medium, rotating speed of the drum etc, which can change drying efficiency.

High heat efficiency. Inner dryer wall plate is weld in spiral, which increase the drying efficiency and larger capacity.

The pin-pin replaceable gear is used to replace the traditional cast steel gear. It greatly reduces the maintenance cost and time.

It can be used to dry powder or granular materials. For those materials with adhesion, it can be equipped with striking device to avoid wall sticking.

Rotary dryers consist of a horizontally inclined rotating cylinder. Material is fed at one end and discharged at the other end. In direct-type rotary dryers, hot gases move through the cylinder in direct contact with the material, either with or against the direction of its flow. The cylinder is equipped with flights, which lift the material and shower it down through the hot gas stream.

| Spec. (Dia.x Length mm) |

Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air Temperature(℃) |

Rotate Speed(r/min) | Main Motor(kw) |

| Φ600×6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800×8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800×10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000×10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000×12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200×8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200×10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200×12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500×12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500×14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500×16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800×12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800×14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800×16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000×18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000×20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200×16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200×18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200×20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400×16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400×18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400×20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600×24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600×28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000×20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 85 |

| Φ3000×25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3200×25000 | 201 | 42.9-53.6 | 3~5 | 700~800 | 1.5~5 | 110 |

*The output will vary according to different materials, feed particle size and other factors