-

WhatsApp Now +86 170 766 13145

-

Any Questions crusher@mgmcrusher.com

How to Operate a Jaw Crusher?

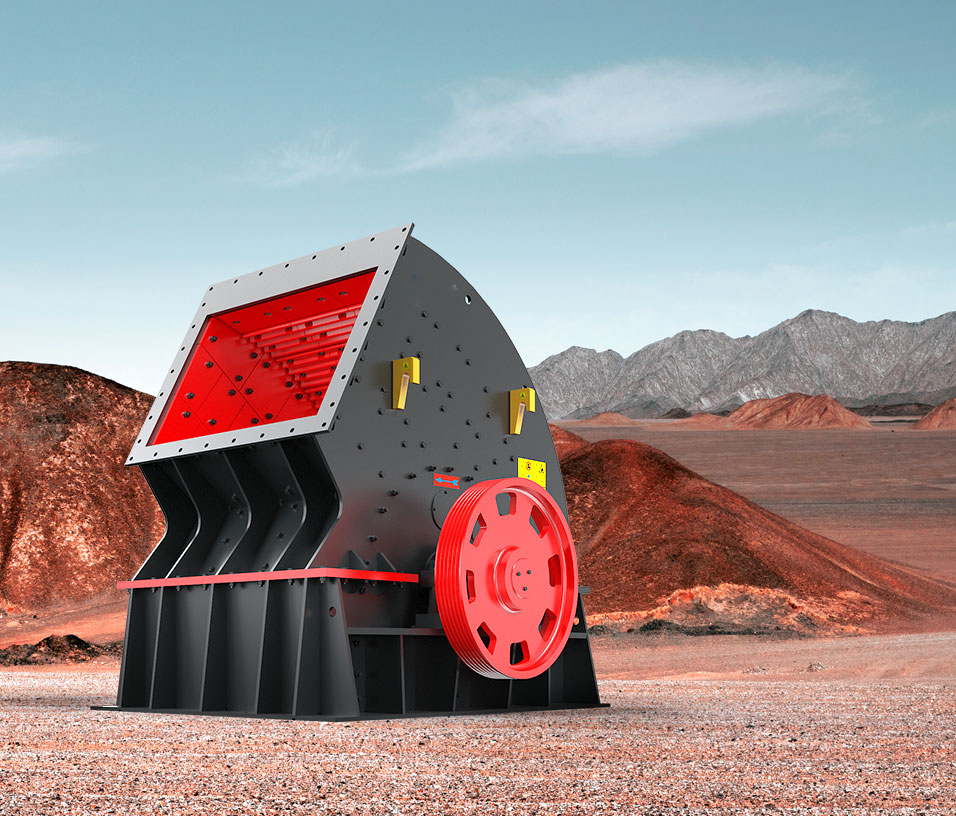

Jaw crusher is a widely used crushing equipment in mining, quarry, building materials, concrete processing industry. It is easy to install ad maintenance following the jaw crusher manual. However, if the installation is not in place or the operation is incorrect, that will effect subsequent production. Let’s explore the steps and attentions to make jaw crusher operation excellently.

Preparations before jaw crusher start

Before starting, the fixed or stationary jaw crusher machine must be thoroughly inspected.

1.Check the wear condition of jaw plate;

2.Adjust the size of the discharge port;

3.Check whether there is stone in the crushing chamber; if there is a large rock, it must be taken out;

4.Check whether the connecting bolt is loose, whether the protective cover of the pulley and the flywheel is intact, and whether the tension of the tie rod spring is appropriate.

Check oil system before jaw crusher motor start

Before starting stationary jaw crusher, the oil pump motor and cooling system should be started first.

1.After 3-4 minutes, when the oil pressure and oil flow indicator are normal, the motor is started.

2.After starting, if the fixed jaw crusher makes an abnormal sound, stop running, identify and eliminate the ills, and restart the machine. The crusher must be started at no load.

Avoid side or full feeding stone at beginning

The operation must pay attention to uniform stone, avoiding side feeding or full feeding. 1. The stone is not allowed to be crowded with the crushing chamber, and the maximum stone size should not be greater than 0.85 times the width of the ore.

2.When the stone is delivered, the non-crushed material is strictly prevented from entering the fixed jaw crusher machine.

3.During the operation, it is necessary to pay attention to the large rock. If it is stuck, use the iron hook to turn the ore; if the large stone needs to be taken out of the crushing chamber, special equipment should be used.

Observe the bearing temperature during operating

In the operation of the machine, if there are too many ore or blockage of the crushing chamber, the ore should be suspended, and the ore in the crushing chamber should be started after being crushed. During operation, it is also necessary to conduct regular inspections to observe the working conditions of the various components and the bearing temperature. The sliding bearing temperature usually does not exceed 60 °C to prevent the alloy bearing bush from melting and causing a burning accident. When the bearing temperature is found to be high, effective measures should be taken to reduce the bearing temperature (such as forced ventilation or water cooling).

Jaw Crusher Attentions

Due to the jaw crusher vibrates heavily during operation, it should be installed on the concrete base. In order to reduce vibration, noise and impact on nearby buildings, between the crusher and the concrete foundation is cushioned with hardwood backing plate, rubber belt or other damping material.

The size of the discharge port should be adjusted according to the required product size. When adjusting, loosen the bolt and tighten the spring. Using the lifting bolt to open the adjusting seat, insert or remove the corresponding thickness of the gasket. Then back up the lifting bolt. The adjusting seat is pressed against the frame ear seat under the action of the moving jaw weight. At the same time, the gasket group is pressed together. After that, adjust the spring pre-pressure to ensure that the machine work. Therefore, the thrust plate and thrust plate pad close. But the pre-pressure should not be too large, not the knock is ok. Finally, a locking adjustment seat.

People Also Frequently Ask For:

1.What are the disadvantages of jaw crusher?

Although jaw crushers work reliably, it disadvantage is output particle size is not so uniform . The size of the output particle size varies with jaw crusher model.

2.How do you increase the efficiency of a jaw crusher?

Ensure that the feed material is properly sized for jaw crusher, and avoid overloading the crusher with oversized material. Also it needs to control the feed speed to avoid overloading and ensure a steady, efficient flow of material through jaw crusher.

3.Why is my jaw crusher not working?

There are some items to check: jaw die and key/heel bolts are tight; bearings is broken; the thrust plate is broken; the connecting rod is damaged; the spring is broken;Repair or replace new part and start jaw crusher again.