Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

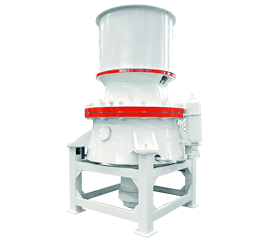

1. The upper and lower ends of DG cone crusher main shaft are supported. It can withstand greater crushing force and greater stroke, so that the machine has higher crushing efficiency.

2. The main shaft of the single-cylinder cone crusher is installed on the bottom hydraulic cylinder, and the bottom hydraulic cylinder can be adjusted up and down to change the size of the discharge port.. This makes the adjustment convenient.

3. The joint surface between the rolling mortar wall and the cone is stable and firm. It could be quick replacement of vulnerable parts without more filling supplements. The replacement time of wearing parts is saved.

4. Double safety control hydraulic and lubrication system can ensure overload protection of the machine and good bearing lubrication.

Simple structure and wearing parts can be changed or repaired easily.

Feeding hooper with high efficient rotation speed makes the wear of the liner plates even and uniform.

Parts adopt high quality steel,reliable performance and operation more safety.

Automatic overload protection to avoid stoppig due to entering of iron lock.

When the single-cylinder hydraulic cone crusher is working, motor drive the eccentric sleeve by v-belts, transmission shaft and transmission gear. Dynamic conerotary pendulum moved with the action of eccentric sleeve, the moving cone and fixed cone sometimes near sometimes deviation. Material is squeezed in the crushing cavity, impact and breakage, broken material discharge from the bottom.

| Model | Cavities | Feeding Size

(mm) |

Adjusting Range of

Discharge Opening (mm) |

Capacity

(t/h) |

Power

(kw) |

| DG100 | Coarse | 150 | 16-40 | 60-125 | 90 |

| Medium | 100 | 14-35 | 50-100 | ||

| Fine | 50 | 10-30 | 40-100 | ||

| DG200 | Coarse | 180 | 16-50 | 120-230 | 160 |

| Medium | 140 | 14-40 | 100-210 | ||

| Fine | 70 | 10-30 | 80-180 | ||

| DG300 | Coarse | 200 | 20-60 | 200-400 | 250 |

| Medium | 140 | 16-45 | 160-350 | ||

| Fine | 90 | 12-35 | 130-280 | ||

| DG400 | Coarse | 230 | 20-65 | 260-500 | 315 |

| Medium | 160 | 16-50 | 200-400 | ||

| Fine | 100 | 12-40 | 160-350 | ||

| DG500 | Coarse | 250 | 20-75 | 350-650 | 355 |

| Medium | 170 | 16-50 | 280-500 | ||

| Fine | 100 | 12-40 | 200-450 |

*The output will vary according to different materials, feed particle size and other factors