Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

Electromagnetic vibrating feeder is widely used in mining, metallurgy, coal, chemical industry, building materials, ceramics and other industries of quantitative feeding.

Electromagnetic vibrating feeder is widely used in mining, metallurgy, coal, chemical industry, building materials, ceramics and other industries of quantitative feeding.

1. The vibration feeder equipment has features of simple structure, uniform feeding, good continuous performance and adjustable vibration force;

2. The structure of the electromagnetic vibrating feeder is simple, the operation is convenient, no lubrication is required, and the power consumption is small; the amount of ore can be adjusted evenly;

3. The flow can be changed and controlled at any time, and the adjustment is convenient and stable;

4. The closed body can be used to prevent dust pollution, and the vibration is stable;

Feed rate can be accurately controlled via a controller.

Few moving parts and does not require lubrication.

Drive can be under trough or overhead mounted.

Suspension or base mounting.

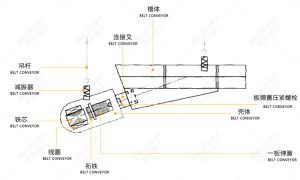

Electromagnetic vibrating feeder works with two eccentric vibration motor based on the self-synchronization principle. It forms a combined force with a 60 ° angle, through periodic vibration, which promote the materials in the trough to slide out, to reach the goal of feeding granular, small block and powder materials to the certain equipment uniformly, quantitatively, continuously.

| Model | Feeding capacity(tph) | Max input size(mm) | Power(kw) | Valtage(v) | Current(a) | Double swing(mm) |

| GZ1 | 5 | 50 | 0.06 | 220 | <=1 | 1.75 |

| GZ2 | 10 | 60 | 0.15 | 220 | <=2.3 | 17.5 |

| GZ3 | 25 | 70 | 0.2 | 220 | <=3.8 | 1.75 |

| GZ4 | 50 | 100 | 0.45 | 220 | <=7 | 1.75 |

| GZ5 | 100 | 150 | 0.65 | 220 | <=7 | 1.75 |

*The output will vary according to different materials, feed particle size and other factors