Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

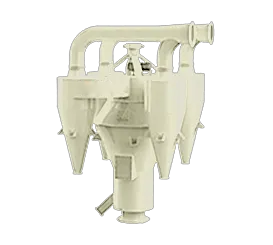

Efficient Powder Separator is the latest powder separating equipment developed by our company, the separating rate could reach 85% -90% or more.

Efficient Powder Separator is the latest powder separating equipment developed by our company, the separating rate could reach 85% -90% or more.

1. Separate the powder material into three class , coarse powder (d>150um), medium-coarse powder (60um<d<150um), and fine powder. The coarse powder is returned to the first silo, and the medium-coarse powder is sent by a high-speed reamer. It enters the grinding bin of the mill (it can also enter the first bin with the coarse powder), and the fine powder as finished product is directly transported into the warehouse.

2. Compared with the centrifugal, cyclone and rotor type powder separators of similar size, Sepax three-separation high-efficiency powder separator has a much higher output, so it is more suitable for the needs of large-scale production. The advanced and reasonable structure allows the powder separation air volume, output and feeding volume to vary in a wide range without affecting the powder separation efficiency, and its classification performance is very stable.

3. Advanced classification principle. Combined with various powder selection principles, the entire flow field is optimized by using aerodynamic analysis methods, which makes the resistance of the equipment significantly reduced and the powder selection efficiency is higher. The material is selected through the powder selection area twice, and the classification accuracy is higher and more accurate.

4. The double interlock air valve is adopted in the coarse powder pipe, medium coarse powder pipe and fine powder pipe, which greatly reduces the air leakage rate of the system and overcomes the defect of large dust in the running process of the previous powder separator.

Particle size distribution is more reasonable, final product quality has been improved significantly.

Using flexible combined propeller bulk plate.

Using low resistance with high efficiency cyclone dust collector.

Spindle speed can be changed by adjusting motor speed, fine adjustment is easy.

Air classifier often work with ball mill, forming a closed- circle production plant.it can improve ball mill capacity and get required material size. it’s widely used for cement production, fly ash production, sand production and so on. more than 300mesh powder can be get. In working condition,high speed motor drives the vertical transmission shaft to rotate through the transmission device. The material access the chamber of separator by the feeding port which on the top of separator, then falls on the scattering plate by two pyramidal which set in the coarse powder collecting cone and powder pipe. The fine powder which satisfied demand will enter inside through the cage rotor,with circulating air enters the high efficiency and low resistance cyclone separator, then slipped into fine powder collecting cone into a finished product.

| Model | S400 | S500 | S600 | S700 | S900 | S1000 | S1100 | S1200 | |

| Matched mill (m) | Φ1.5 | Φ1.83 | Φ2.2 | Φ2.4 | Φ3.0 | ||||

| Motor Blower | Model | YCTL200-4A | YCTL200-4B | YCTL200-4A | YCTL200-4B | YCTL200-4B | YCTL200-4A | YCTL200-4A | YCTL200-4B |

| Rotating speed(r/min) | 125-1250 | 132-1320 | 440-1340 | 440-1340 | 600-1340 | ||||

| Power (KW) | 7.5 | 11 | 15 | 18.5 | 37 | 55 | 75 | 90 | |

| Model | SCF-12NO.8C | SCF-12NO.8C | SCF-12NO.10C | SCF-12NO.12C | SCF-12NO.12C | SCF-12NO.16B | SCF-12NO.16D | SCF-12NO.12C | |

| Volume | 24216 | 30900 | 37960 | 58200 | 119332 | 168000 | 192000 | 211000 | |

| Air pressure | 2.18 | 2.43 | 2.34 | 2.07 | 2.26 | 2.70 | 2.70 | 2.60 | |

| Rotating speed(r/min) | 1500 | 1600 | 1200 | 1000 | 800 | 960 | 960 | 710 | |

| Model | Y180M-2 | Y200L1-2 | Y225S-4 | Y225M-4 | Y335M1-8 | Y335M1-6 | Y335M3-6 | Y335L-8 | |

| Power (KW) | 22 | 30 | 37 | 55 | 132 | 160 | 200 | 220 | |

| Rotating speed of shaft (r/min) | 190-380 | 190-380 | 150-350 | 150-350 | 140-350 | 100-300 | |||

*The output will vary according to different materials, feed particle size and other factors