Inquiry Now

Email: crusher@mgmcrusher.com

WhatsApp:+86 170 766 13145

PFCK is reversible impact hammer crusher combines the advantages of hammer crushing and impact crushing. The biggest feature is that the rotor can be reversed, which improves the utilization rate of the hammer head of the crusher. It can also crush material.

PFCK is reversible impact hammer crusher combines the advantages of hammer crushing and impact crushing. The biggest feature is that the rotor can be reversed, which improves the utilization rate of the hammer head of the crusher. It can also crush material.

It has reasonable structure, equipped with the buffering and damping device. The machine body shocks small with lower noises and high strengthen.

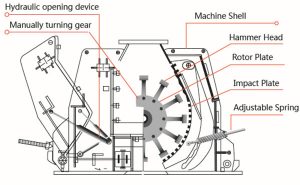

Monitoring door are set reasonably. Hinges for upper and bottom machine body, open the upper cover by hydraulic controlling, convenience to maintain and inspect.

It is designed with regulating part to adjust the pre-tightening force of spring easily to control the discharging size effectively and satisfy the crushing ratio.

This crusher machine makes rotor rotate reversely, so it can prolong the service life of hammer and reduce the frequency of maintenance.

The machine body is hydraulically opened, and the easily worn parts are easy to change.

With Fluid coupling design. reversible hammer crusher is efficient.

Straight in and out material, not easy to plug material.

Spiral hammerhead layout, high crushing efficiency.

After the falling material enters the reversible impact hammer crusher, it encounters the high-speed rotating hammer head; it is hit by the adjustable wear-resistant tooth plate at the entrance of the crusher for the first crushing, and the crushed materials have basically the same particles Evenly enter the main crushing cavity for secondary primary crushing, and the material particles that have been homogenized in the primary crushing cavity obtain kinetic energy from the hammer head again. It rushes to the sawtooth liner inside the impact chamber at high speed, rebounds upwards from the sawtooth liner, and is crushed by the hammer again. At the same time, the materials are also crushed by the impact of each other, and the cycle repeats. After repeated crushing in the counterattack cavity, the crushed materials are finally discharged from the discharge port, and the finely crushed materials are the final products.

| Model | Rotor size(mm) | Input Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kw) |

| PFCK0808 | φ800×800 | <60 | <15 | 25-40 | 90 |

| PFCK1010 | φ1000×1000 | <80 | <15 | 35-70 | 110 |

| PFCK1012 | φ1000×1250 | <80 | <15 | 70-80 | 132 |

| PFCK1212 | φ1250×1250 | <100 | <15 | 90-120 | 220 |

| PFCK1214 | φ1250×1400 | <100 | <15 | 120-150 | 250 |

| PFCK1416 | φ1400×1600 | <120 | <15 | 160-250 | 355 |

| PFCK1418 | φ1400×1800 | <120 | <15 | 250-300 | 400 |

| PFCK1618 | φ1600×1800 | <140 | <15 | 280-350 | 560 |

*The output will vary according to different materials, feed particle size and other factors