Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

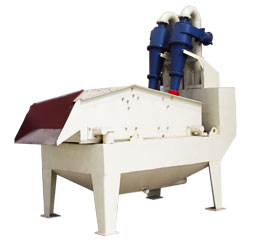

Fine sand recycling machine, also known as fine sand collection machine, fine sand extraction machine, fine sand recovery machine etc.It could be used for dewatering, removing and removing mud materials.

Fine sand recycling machine, also known as fine sand collection machine, fine sand extraction machine, fine sand recovery machine etc.It could be used for dewatering, removing and removing mud materials.

The fine sand recycling machine can effectively reduce the loss of fine sand and the content of stone powder in the tail water, which solves the problem of high fineness mold of finished sand and low content of stone powder in the artificial aggregate processing system.

Fine particles are fully recovered, reducing the workload of cleaning cost of the sedimentation tank.

The vibrating screen produce by Baichy machinery adopts polyurethane screen with longer life than other types of screen, and will not block holes.

Making customerized machine according to different demands.

Effectively reduce the fine sand losing quantity.

Reduce the amount of fine material piling up, can be directly transported to supply market.

The vibrating screen is polyurethane screen cloth, which has longer life and smoothly finishes the work of condensing slime and clearing the liquid.

The pump sends the sand and water mixture to hydrocyclone, the fine sand with eccentricity is sent to vibrating screen. The fine sand and water are effectively separated after dehydration, and little fine sand and mud go back to washing trough. When the liquid surface of the washing trough is high, the fine sand discharges from output opening. The linear vibrating screen can recover material with concentration 70%-85%. Adjusting fineness modulus can be realized by changing pump rotation speed, changing pulp consistency, adjusting overflow water and changing sand sinking mouth. By the process above, the fine sand recovery system can finish three functions, cleaning, dehydration and grading.

| Model | Pump Power (kw) |

Separator Spec (mm) |

Dewatering Screen | Capacity (m³/h) |

|

| Spec(mm) | Power (kw) | ||||

| FX250 | 11 | 250 | 800×2000 | 2×0.75 | 30-60 |

| FX300 | 15 | 300 | 800×2000 | 2×0.75 | 60-100 |

| FX350 | 18.5 | 350 | 1000×2000 | 2×1.5 | 70-130 |

| FX550 | 22 | 250×2 | 1200×3000 | 2×2.2 | 100-220 |

| FX650 | 30 | 300×2 | 1500×3000 | 2×3 | 120-272 |

| FX750 | 37 | 350×2 | 1500×3000 | 2×3 | 180-350 |

| FX900 | 55 | 300×3 | 1800×3600 | 2×4 | 450-650 |

*The output will vary according to different materials, feed particle size and other factors