Inquiry Now

Email: [email protected]

WhatsApp:+86 170 766 13145

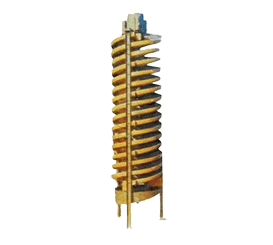

Spiral chute is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion.

Spiral chute is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion.

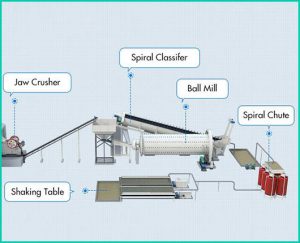

1. Gravity separation is one of the commonly used methods for gold ore beneficiation. It uses different specific gravity of materials and different sedimentation speed in the medium to carry out layered separation. Generally, in placer gold ore, gold is mostly in the form of monomer natural gold. When it exists, the density difference between it and the gangue is relatively large, and it is effective and economical to use for gravity separation of gold.

2. The spiral chute is suitable for processing fine-grained materials with low mud content. The material particle size ranges from 0.6 to 0.03 mm. It has a simple structure, large processing capacity, and low overall cost.

3. In the gold ore dressing, the selection of gravity separation needs to be determined according to the nature of the gold ore. It is suggested to select the beneficiation test in the process selection, analyze the nature of the gold ore, and finally determine whether the gravity separation process is suitable for selection according to the test, or determine which gravity separation process is more suitable through the test.

Material quality material quality with features of moisture resistance

Stable and clear mineral separation with large handling capacity.

High adaptability of the feeding capacity and the variability of concentration,

High efficiency with higher concentration ratio and high recovery.

Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones——concentrate, middling and tailing

| Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

| Outside Diameter (mm) | 1500 | 1200 | 900 | 600 | 400 |

| Screw Pitch (mm) | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 |

| Pitch Diameter Ratio | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 |

| Lateral slope (degree) | 9° | 9° | 9° | 9° | 9° |

| Max. Screw Numbers | 4 | 4 | 4 | 2 | 2 |

| Feed size (mm) | 0.8 ~ 0.037 | 0.3 ~ 0.03 | 0.3 ~ 0.03 | 0.2 ~ 0.02 | 0.2 ~ 0.02 |

| Feed Density (%) | 30 ~ 55 | 25 ~ 55 | 25 ~ 55 | 25 ~ 55 | 25 ~ 55 |

| Capacity (t/h) | 6 ~ 8 | 4 ~ 6 | 2 ~ 3 | 0.8 ~ 1.2 | 0.15 ~ 0.2 |

| Length (mm) | 1600 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 1600 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 5300 | 5230 | 4000 | 2600 | 1500 |

| Weight (kg) | 850/800 | 700/650/600 | 450/400/350 | 150/120/100 | 50 |

*The output will vary according to different materials, feed particle size and other factors