Inquiry Now

Email: crusher@mgmcrusher.com

WhatsApp:+86 170 766 13145

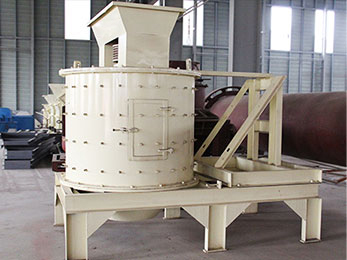

PFL compound crusher is kind of vertical shaft sand making machine. It is adjustable fine crushing equipment without screen bar and suitable for crushing brittle materials with medium hardness and low water content.

PFL compound crusher is kind of vertical shaft sand making machine. It is adjustable fine crushing equipment without screen bar and suitable for crushing brittle materials with medium hardness and low water content.

Why choose vertical crusher?

The composite crushing hammer and rotor are rigidly connected, and the inertia of the whole rotor is used to impact material, which can obtain greater speed and kinetic energy, making it easier to crush and lower energy consumption.

The structure of the crushing cavity is designed to be large, so that the material has a certain space for movement in it. The material is impacted and can be fully broken after repeated blows.

The impact crushing steel disc structure and the hammer disc are staggered. This kind of new design enhances the working performance of the crusher effectively .

The combined structure of hammer head make it easy to replace severely worn parts only. It greatly improves the service life of the hammer head, and effectively reduces the production cost and the replacement frequency of the wearing parts of the equipment.

Good sealing and dust removal device eliminate dust pollution to meet environmental standards.

Large crushing ratio, discharging particle size can be adjusted arbitrarily, not affected by wear of hammer and liner plate.

Without screen bar, it is not easy to block when crushing materials with high moisture content and mud content.

The unbreakable material can be discharged automatically due to elastic adjustment mechanism and crusher machine will not be damaged.

Materials drop into high speed rotating impeller in vertical, under high speed centrifugal force, stroked and crushed with materials scattered around the impeller in umbrella, after repeatedly impacting then there will be forming eddy current between the impeller and frame, materials will be crushed again and finally discharge from outlet directly, whole system formed closed circuit, separated by outer screen to control fineness.

| Model | Feeding Size(mm) | Output Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension (L*W*H) |

| PFL-800 | < 50 | < 3-5 | 10-20 | 22-37 | 2100*1200*1700 |

| PFL-1000 | < 80 | 20-40 | 45-75 | 2600*1400*1900 | |

| PFL-1250 | < 150 | 40-70 | 75-132 | 2800*1600*2100 | |

| PFL-1500 | < 180 | 70-100 | 132-200 | 3100*1900*2200 | |

| PFL-1750 | < 200 | 130-190 | 200-315 | 3710*2360*2390 | |

| PFL-2000 | < 220 | 200-260 | 315-355 | 4100*2660*2620 |

*The output will vary according to different materials, feed particle size and other factors